플랜트 자동화

Be automation with CNA SYSTEM

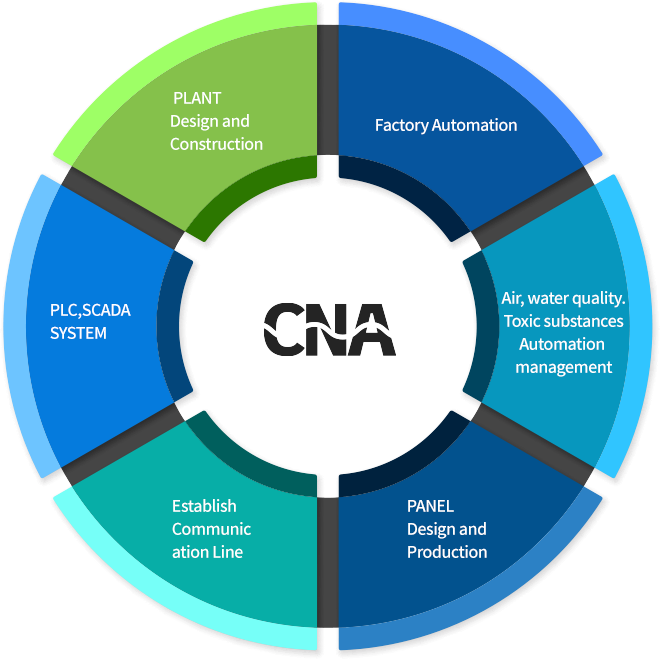

The purpose of CNA's automation technology is to provide products and solutions for digitalization by integrating companies of any size or type into automation.

We support boosting the flexibility and environmental efficiency of the production process, including the design of electrical and electronic products, production lines, and communication required. Industrial sites use automated products and more efficient software, solving rather complex problems with reliable analysis.

With the use of Programmable Logic Controllers for automatic control and the use of Continuous Emissions Monitoring System or User Interface applied to each site, CNA strives to make the most of its data potential to save time, prepare for risks, and approach confident business.

<MALAYSIA PRAI CCGT PROJECT>

Eco-plant

Numerous power plants and factories are built in the global market.

Environmental protection is an essential task in this situation.

Pollutants that threaten the air and water quality are released during factory operation, and in the past, they required a lot of equipment and work force to filter, purify, operate, and maintain them. In addition, in the process of finally discharging filtered and purified substances, manpower is directly deployed to measure pollution levels for a certain period and report them to the environmental bureau in each nation. As such, it is prominent to build eco-plant automation system to avoid the risks everywhere and its difficult to track back various device errors.

The construction of eco-plant automation enables four main things.

- 1) It is possible to check each area at each control station through a long-distance communication network with sensors in

dangerous places for manpower placement - 2) Alarms occur when the measurement standard of pollution level is out of line or equipment error occurs.

- 3) All filtration, purification, and discharge processes are also recorded and monitored by the control station.

- 4) The recorded data will be reported smoothly to the environmental bureau.

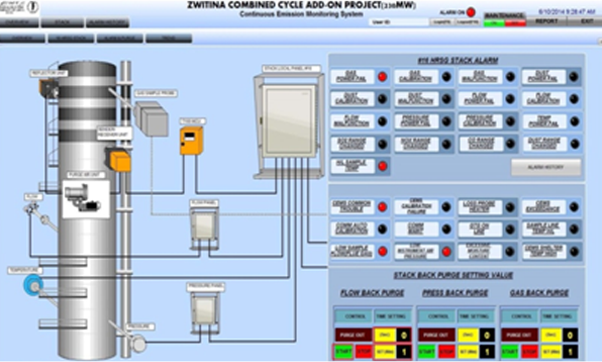

<ZWITINA COMBINED CYCLE ADD-ON PROJECT>

Application for CEMS

- · Human Machine Interface <Used Make>>

- · Programmable Logic Controller <Used Maker>

- · Subsidiary User Interface Program <Program Language>

- · Transmission to the Environment Admin Data Interface System

<Program Language>

- · Between the equipment Communication Software

(232,485,TCP/IP,Modbus..etc) <Program Language>

- · Panel manufacturing

- · Sensor and Indicator sales

Partner Company

- · Human Machine Interface <SIEMENS, AB, GE, Schneider, LS, Cimon..>

- · Programmable Logic Controller <SIEMENS, AB, GE, Schneider, LS, Cimon..>

- · Communication Convertor(232,485,TCP/IP,Modbus..etc)

<Moxa, Gigbee, Soltech, Adam…>

- · Touch Pad <SIEMENS, AB, Advantech, LS, Cimon..>

<Program Language>

(232,485,TCP/IP,Modbus..etc) <Program Language>

- · Human Machine Interface <SIEMENS, AB, GE, Schneider, LS, Cimon..>

- · Programmable Logic Controller <SIEMENS, AB, GE, Schneider, LS, Cimon..>

- · Communication Convertor(232,485,TCP/IP,Modbus..etc)

<Moxa, Gigbee, Soltech, Adam…> - · Touch Pad <SIEMENS, AB, Advantech, LS, Cimon..>